The last part needed before I can do some more running and test the hit ‘n miss governor, is to mount the hall effect sensor and timing magnet for the ignition.

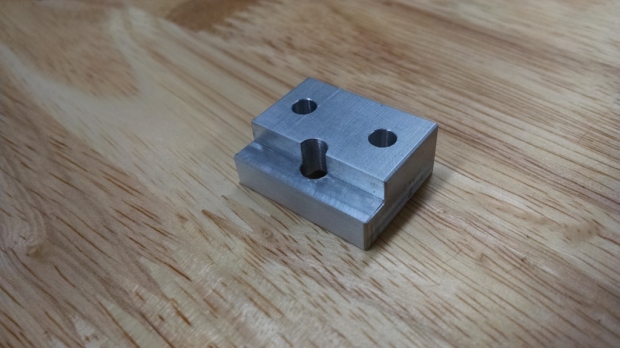

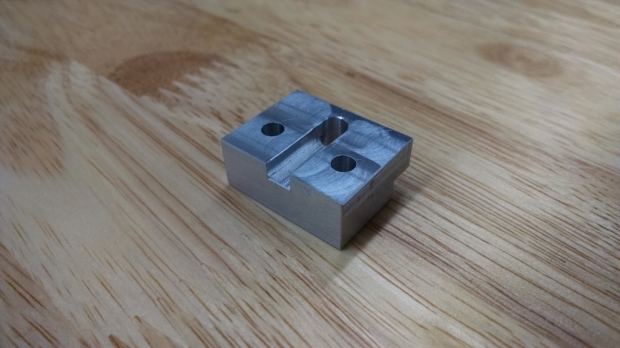

I made a block to mount the hall effect sensor.

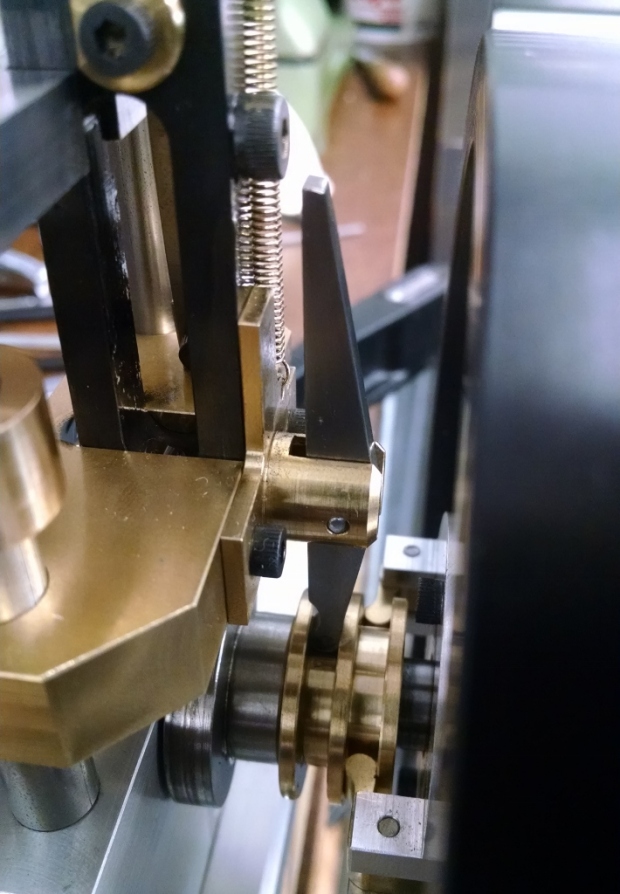

The hall effect sensor and block mounted on the engine.

To mount the timing magnet, I made a ring from aluminum and it will be secured on the crankshaft with a set screw.

Now that we have all the pieces together, its time to let the engine run some more and see how the governor works.

I gave the engine a good shake down run and I’m very pleased how the engine runs.

After running the engine for a while, I started noticing a couple of issues I’ll need to address.

The first and biggest issue, is my built up crankshaft. I was getting a bit of flex in it, and with the big flywheels, there was a definite wobble noticeable. Even though my idea of building it up the way I did was a failure, I’m OK with it. I had to try it, and that’s how we learn.

Anyway, I’m remaking the crankshaft. It will be built up again, but the more “traditional” way.

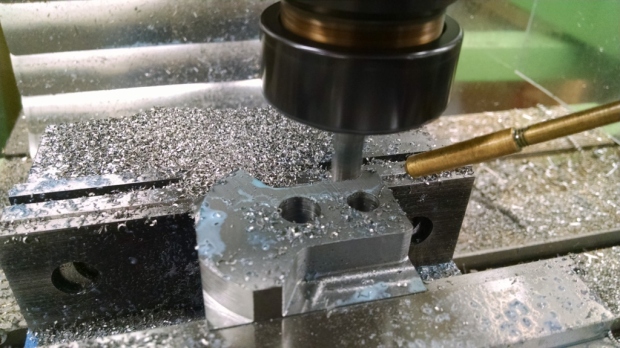

First, I milled out a couple crank webs. As I was at it, I made a small cosmetic design change to the webs.

I used a boring head to bore the two holes, to ensure that they are accurate and parallel.

The shafts and pin are made out of drill rod, and are ready for assembly.

I assembled the crankshaft with Loctite and set screws, and it’s ready to go back into the engine.

An other issue that needed to be addressed was the latch. I made the first one out of brass. It wore out very quickly, which was no surprise. My intentions where to modify it by attaching a small steel plate, that could handle the wear. Unfortunately, in the process of modifying, I messed up the part.

So I had to make a new one. I decided to make it out of O-1, and harden the business end of it. That will take care of any future wear issues.

First, I milled out the part. Second operation was in soft jaws to mill off the rest of the material and mill it to thickness.

And the latch back on the engine.

Thank you for visiting my shop.

If you have any questions, please feel free to leave a comment and I’ll get back to you.

Yogi

Hi Yogi, I have followed you build of the Duclos gearless. I have built quite a few engines and have had good success. However with this one I have very good compression and have adjusted the timing as per Phils directions. I get a very short run about a few seconds never picking up many rpms. On the next spin the same happens again. I have played with the carb needle from closed to many turns open.. I have played with the point timing to no avail. I”am at a point total frustration. It will fire almost every spin but will not continue to run. Yogi any suggestions will be appreciated.

LikeLike

Hi Edward, I’ll try to help you out as much as I can. The first thing I always check when an engine doesn’t want to run right is friction. Even the slightest amount of friction can cause the engine not wanting to run. The other things to check are, like you already mentioned, carburation and ignition. The carburetor that has worked well for me, and is also on the gearless engine is a vapor carb. It might be helpful to build yourself a small test vapor carb (like the one I use on my SAM engine) for troubleshooting purposes. When I built the gearless engine, I used it for the first test runs (see episode 7). By the sound of it, your engine is firing, then I think your ignition is working ok.

I hope this helps, and please contact me at yogisworkshop(at)yahoo.com to continue our conversation.

Yogi

LikeLike