We are getting really close to see if there is life in these engines. The last thing needed before a test run, is the valve train. These parts are very time consuming, requiring a number of different set ups.

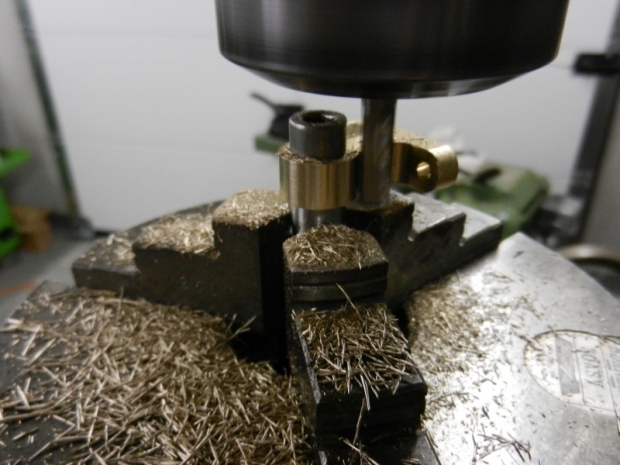

No CNC equipment in my brothers shop (at the time of this build. He has since added some new equipment to his shop). To make the radius on the parts, we used a fixture to hold it in the dividing head.

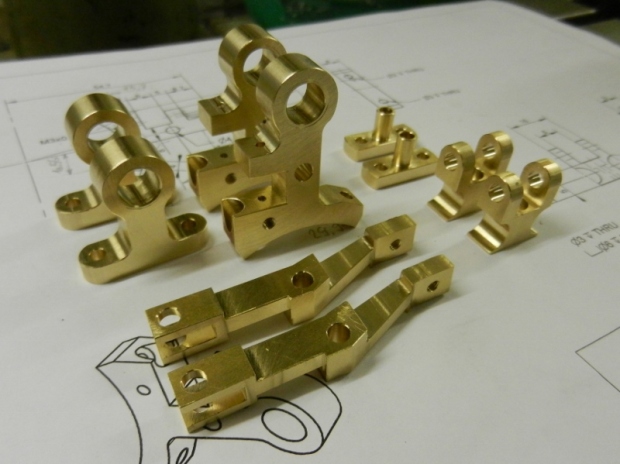

The (almost) finished parts…

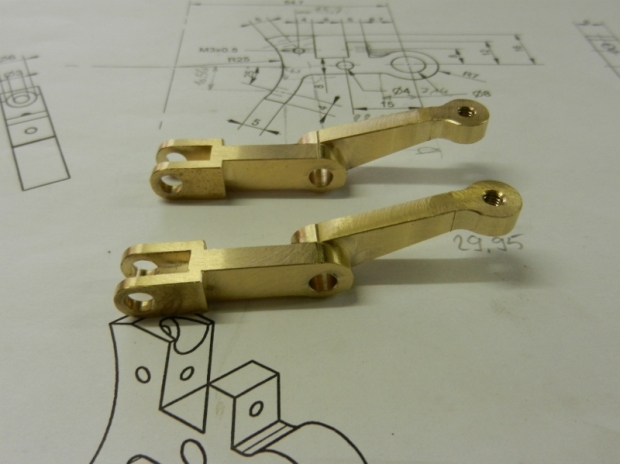

…as the rocker arms needed the radii added.

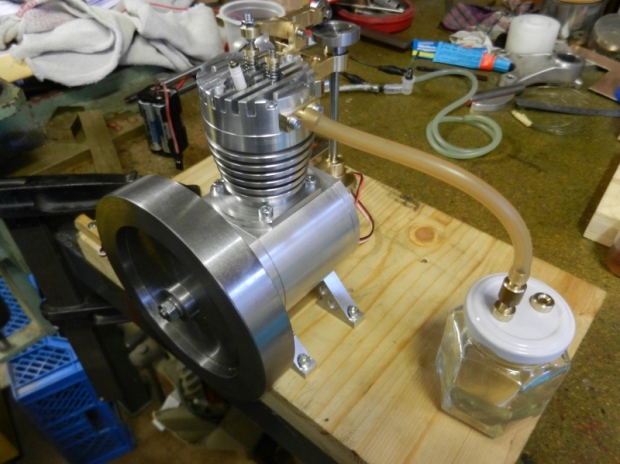

Now we have everything together, and are ready to give it whirl.

And lo and behold, the engine fired right up on the very fist try!

We where prepared to spend some time adjusting and tinkering, as on some of our previous engine builds, a considerable amount of fiddling was required to get them running. No need on this one, it ran beautifully.

This was our first internal combustion engine we built. The excitement was enormous.

This was at the end of day 8 of the project. Now we have two more days to finish the hit and miss governor and put the finishing touches on to the engines.

Thank you for visiting.

For other project from my shop, see the projects page in the top menu.

If you have any questions, please feel free to leave a comment and I’ll get back to you.

Yogi

Great work on the brass parts and the whole engine ! Bring some of that ” starts first time with you ” ! 🙂

LikeLike

Thanks Brian! Yea, lets hope we’ll have another first start tomorrow… 😉

LikeLike