I have been cutting down a lot of trees on my property, to expand the yard. The clearing of the trees has been going well, but I needed to find a solution for the left over stumps. It became very clear to me that grinding would be the preferred method to deal with them.

I started an evaluation process, to figure out how I would proceed. The following are some of the options I considered:

- Rental Equipment. Renting a stump grinder seems very economical at first; especially if there are only a few stumps to grind, but as the “yard expansion project” will extend over a rather long period of time, and I’ll be working on it as time and weather allows, it would become less so.

- Hand Operated Sump Grinder. It takes a lot of effort to operate one of those, and for just a stump or two would be a good option. For the amount of stumps I have to grind, I would prefer something more mechanized. The least expensive one I could find was around $2000. A lot of money for a gas engine on a steel frame.

- Second Hand Professional Machine. It’s a big investment. The asking price for any used stump grinder I could find was upwards of $5000. These machines are purpose built an would do a wonderful job, but it’s just not in the budget. Also, those machines are rather large, and I would not have a good place to store it when not in use.

- 3-Point, PTO Driven Grinders. That’s the ticket! Powerful machines, using the tractor PTO, and hydraulics to operate it. But here comes to problem: My tractor! My tractor is a Yanmar SC2450. The tractor falls into the sub-compact category. Even though the tractor has a cat-1 hitch, hydraulics with a 24 hp engine, I felt all the commercially available grinders would be too big for this little tractor. The cost of purchasing such unit is prohibitive too, as they start at around $4500.

In the end, I decided to build my own version of a PTO driven stump grinder, that would be properly sized to fit my tractor. Aside from building a stump grinder that fits my tractor, It will also be the least expensive option.

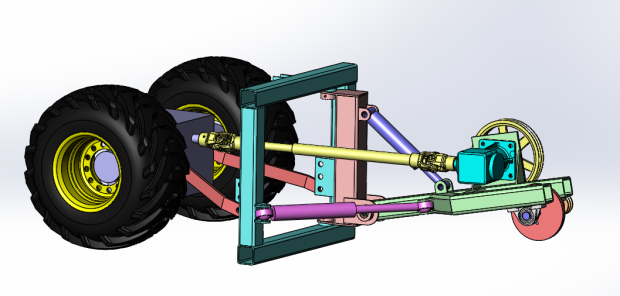

First, I modeled it in 3D CAD.

I also modeled the hitch and PTO of the tractor to ensure that the drive shaft will clear the frame in all possible positions.

Some of the design considerations:

- The frame is to be lowered to the ground for grinding. This will transmit the cutting forces into the ground, rather than into the tractor.

- The gear box is from a rotary mower, turned horizontal.

- The cutting disc is a compact 11 inches, as this is the largest size for my small lathe.

- Greenteeth carbide teeth and pockets. www.greenteeth.com

- Belt drive to increase the cutting disc rpm, to make up for the small diameter disc.

- Off the shelve hydraulics. www.surpluscenter.com

I’m ready to start cutting metal, which we’ll see in the next episode.

Thank you for visiting my shop.

If you have any questions, please feel free to leave a comment and I’ll get back to you.

Yogi

Fantastic design, i think i will build one similar to this. Couple questions.

1) Would you go to a bigger wheel? (what HP is your tractor?)

2) Any info on size of gearbox?

3) Any other changes you would make?

Thanks

Derek

LikeLike

Also, what speed are you spinning the disc?

LikeLike

I can’t remember the exact rpm I calculated, but I think it’s around 1500-2000 rpm.

LikeLike

Hi Derek, thanks for the comment.

1) A bigger disc would be nice. The size of the disc I chose was due the the size of equipment I have to build it. The tractor is rated at 24HP. It has no problem grinding. If I’m taking a to aggressive cut, the v-belts will start to slip.

2) The gearbox was sourced from eBay. It’s a rotary mower gearbox turned sideways.

3) I can’t really think of any changes I would make at this point… I’m still happy how it performs.

Best Regards,

Yogi

LikeLike

Good to hear.

My tractor is rated at 14hp so not sure if i would want to go bigger on the wheel.

LikeLike

What thickness is the cutting wheel and what size shaft did you use?

LikeLike

The disc is 3/4” and the shaft is 1 1/4”

Sorry for the late response.

LikeLike

Good post, I think this is why I will develop my PTO stump grinder.

LikeLike